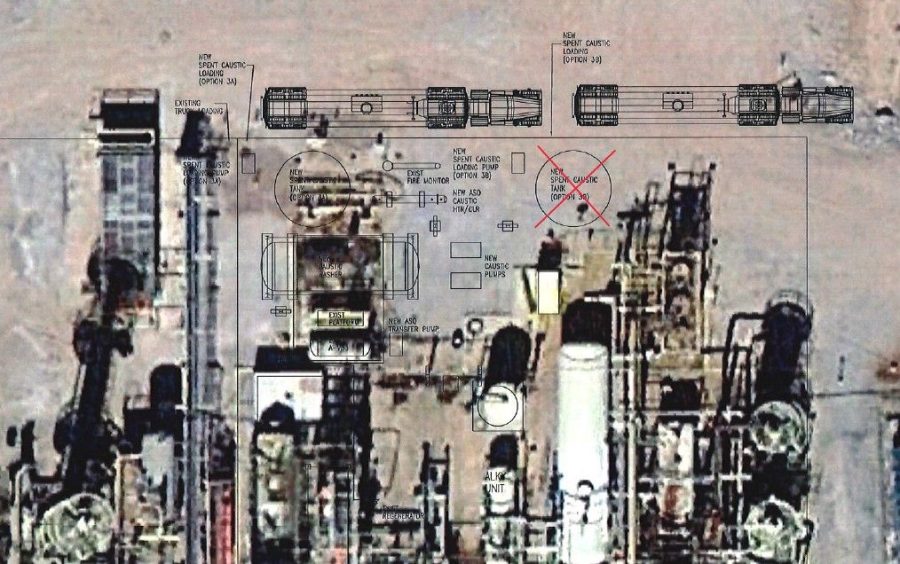

ASO System Revamp for HF Alky Unit

Leveraging our previous experience with Acid Soluble Oil (ASO) Washer Systems, our team provided insight on how systems are configured at similar sites to thoughtfully execute the Feasibility phase of the project. At this facility, the current ASO neutralization and spent KOH handling system in the Hydrofluoric Alkylation (HF Alky) unit is a labor-intensive batch process that has many environmental and safety concerns. The system will be replaced with one that is similar to a ConocoPhillips (now UOP) ASO Washer system used at multiple other refineries. This will reduce the likelihood of environmental releases of HF acid and operator exposure to caustic, ASO and HF acid that are present during the manual process. As an added benefit, the new system will also result in operating cost savings.

The project will design and commission equipment which allows for continuous, closed loop treatment of ASO within the HF Alky unit. As a cost savings, existing equipment will be repurposed where safety or integrity is not compromised. Drawing upon our experience from other refineries, our process team scaled the technology to match refinery flow rates based on comparison of ASO to Caustic ratios from other existing units. Our support on this project extended beyond creating a cost estimate, we also attended our client’s presentation to management. We not only care about project design, but the entire project process and are here to help our clients in any way we can!