Soap Blending and Filling Expansion

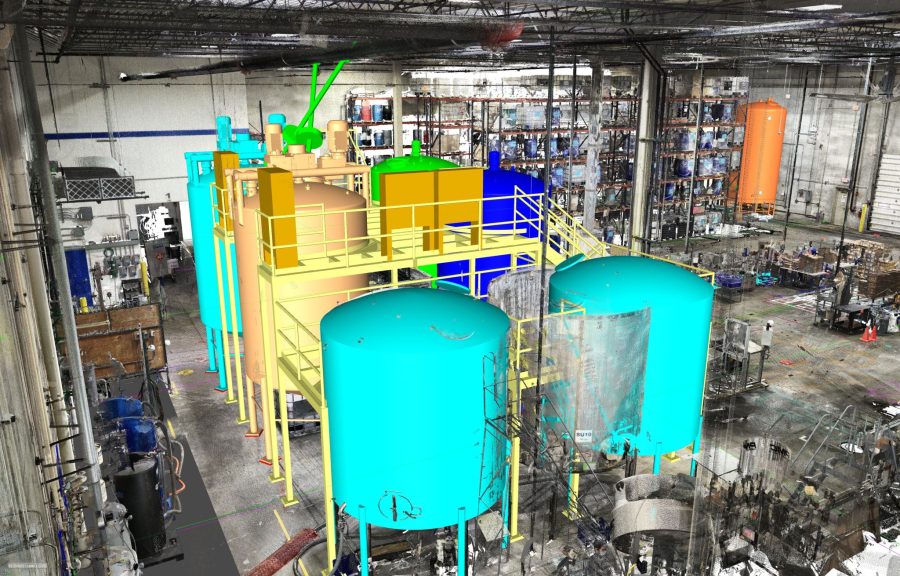

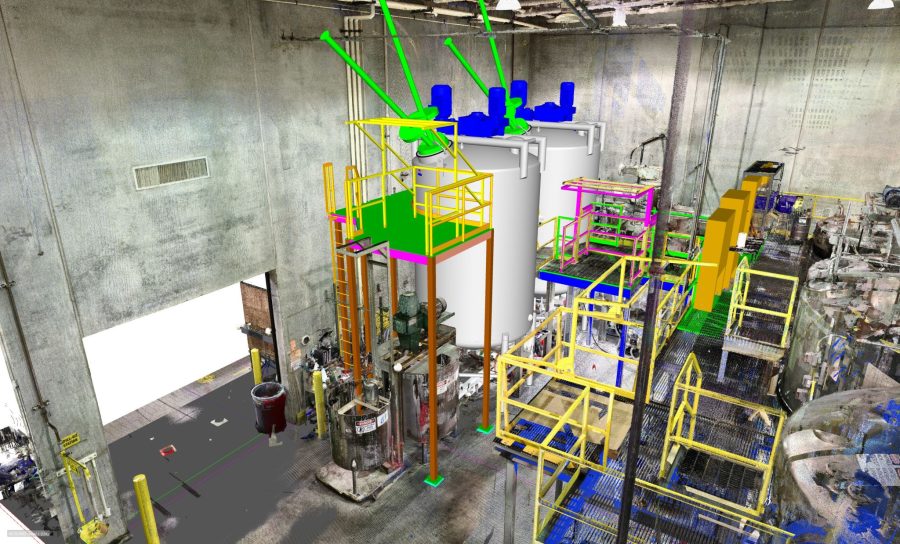

Our team added 24,000 gallons of blending capacity for soaps and similar products within an existing facility, in addition to adding to its filling/packaging capacity. The project team had to fit new batch and surge tanks within the space constraints of the existing compounding facility, while ensuring that the needs of Operations and Maintenance were met. Additionally, our design had to be versatile enough to accommodate a variety of products and container sizes.

We worked alongside the client to develop an understanding of the technical requirements, including the information needed for raw materials and product recipes. We also worked with conveyor and equipment manufacturers to install, relocate, and modify production lines to meet the needs of the client.

Project scope included:

- Four new 6,000 gallon blend tanks

- Four new 6,000 gallon surge tanks

- Two new pre-mix tanks (350 gallon and 500 gallon)

- Two new 10,000 gallon FRP surfactant tanks

- New mezzanine for two blend and two surge tanks

- Modified mezzanine for two blend tanks

- New sanitary valves, transfer pumps, instrumentation, and VFDs

- New/relocated packaging equipment, including a bottle unscrambler, filler, cap torquer, labeler, case erector, drop packer, and case sealer

- New conveyor for packaging line

- Relocation of a packaging line from another facility – modified layout