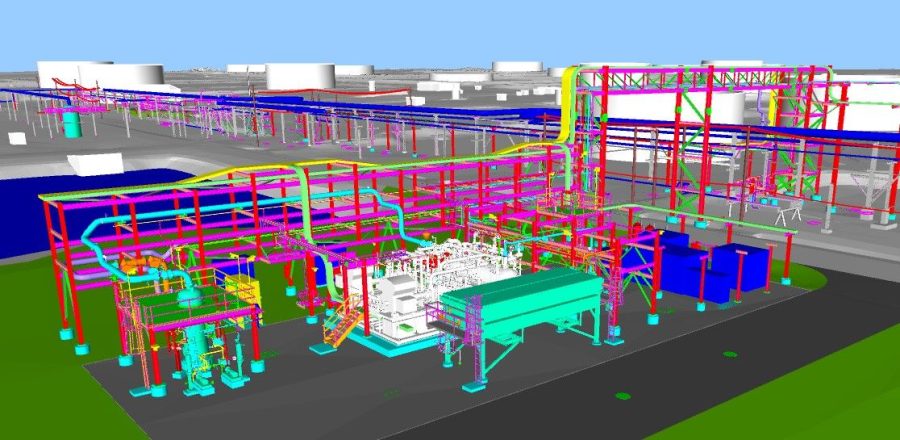

Flare Gas Recovery Compressor

Our team worked with the client to address their flare gas consent decree, targeting high concentration H2S streams. Two approaches were taken. For one flare system, a new liquid ring compressor was installed. For the second flare system, we evaluated alternate technologies for reducing H2S through upgrades in the amine and sour water systems as an interim measure to meet the decree, ultimately lowering overall project cost.

There were three streams that the system could not recover, therefore C&I identified a method for recycling them back to the plant. By recycling these streams, we were able to save $3MM in total installed costs. We were one of the first to install this new compressor and worked directly with the vendor (SIHI) to ensure smooth engineering and install and to provide a reliable system for emissions reduction.

The site selected for the compressor required significant prep work, including filling in a pond and reworking drainage to other sewer systems. Our team routed over a mile of large bore piping, including a new pipe bridge, to tie the systems together.