Alky Butane Defluorinator

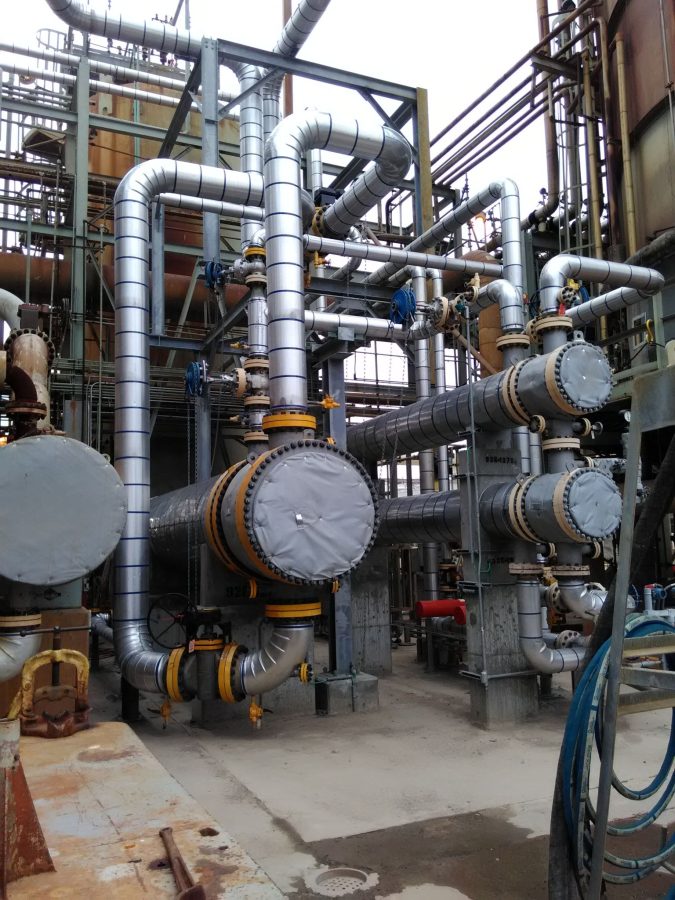

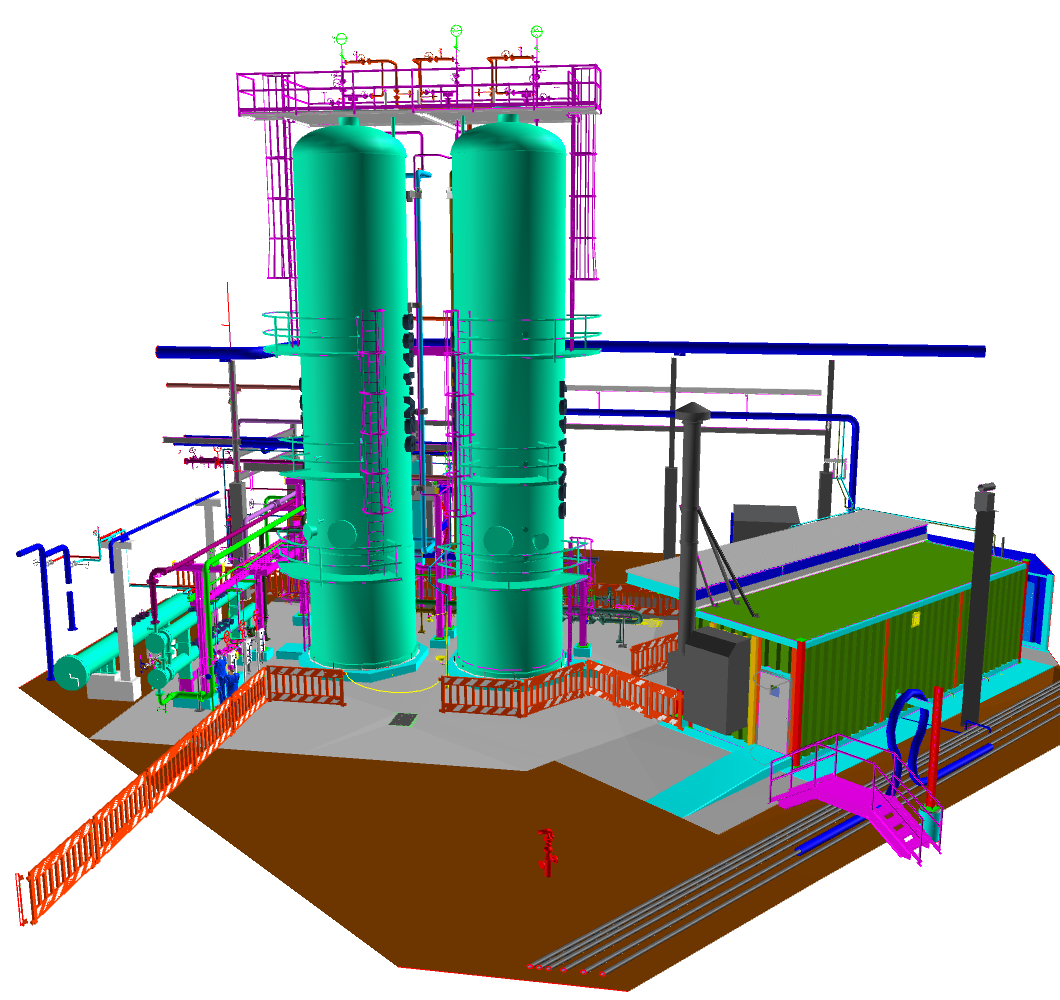

C&I managed the Alky Butane Defluorinator project from Conceptual through Detailed Design. Working in conjunction with UOP, we specified the design for installing a new Defluorinator reactor to remove organic fluorides from the butane stream. This removal step prevented corrosion issues in the downstream processing unit, eliminating the need to send the product to the butane caverns. The existing KOH Treater was deemed insufficient to process the additional water generated from the Defluorinator; therefore, a parallel KOH Treater was installed as part of the project. Due to the composition of the butane stream, heat integration at higher than normal temperatures was required prior to treatment in the Defluorinator, requiring coordination with UOP to address the feed temperature requirements. C&I performed a process study of the downstream processing unit to identify any constraints with processing the additional butane with heavier C5+ components. To save costs and reduce construction downtime, the foundation for the defluorinator was optimized to accommodate a specialized crane for vertical lifting of the vessel.

C&I provided cost estimates at each phase gate for funding approval, procurement for instrumentation and engineered equipment, and construction packages.

The project started in mid-2015 and concluded in late 2019. Our team completed the project under budget and with very few adjustments or disruptions. With a condensed schedule and significantly long lead deliverables and delays, we worked well under the pressure to produce a quality outcome. Operations was prioritized so that the new layout was intuitive, safe, and accessible.

What We Did...

What This Client Said

“We would like to express our recognition and appreciation for how well the Defluorinator project TAR, commissioning, and start-up was executed. There were zero safety, environmental, process, or operations issues as the project was completed and placed into operation. The equipment quickly began meeting the operational process objectives set for the project and the team delivered a quality installation that is performing at or better than objectives required.”