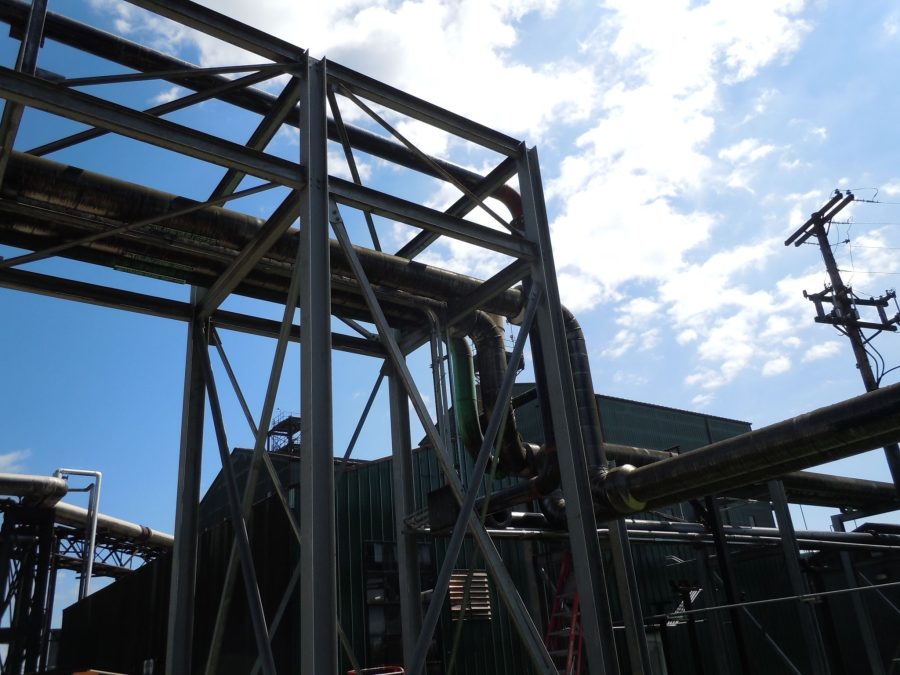

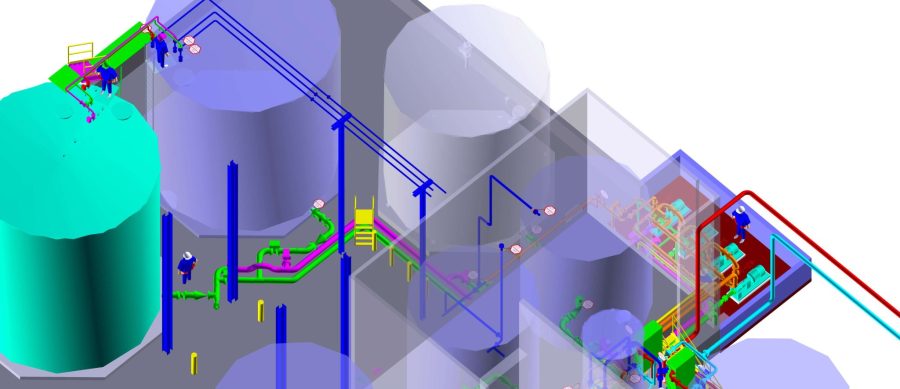

Hydraulic Improvements and Capacity Increase

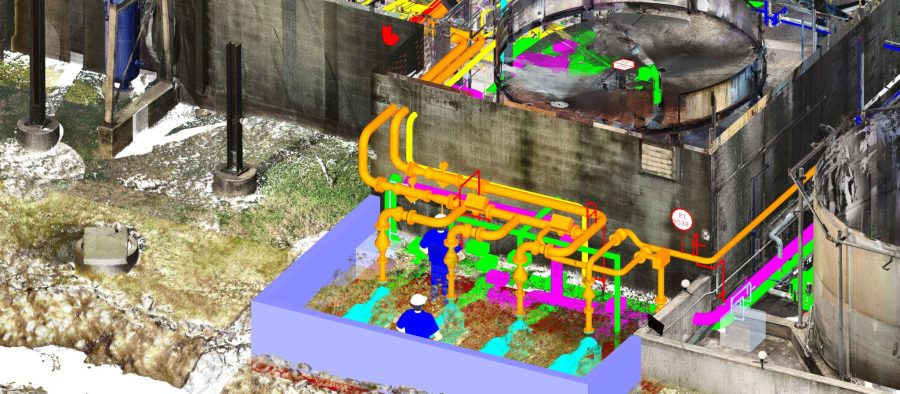

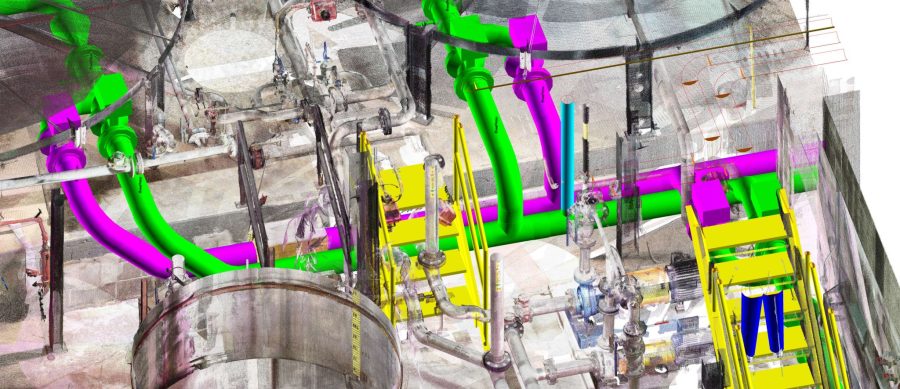

Our team upgraded the equipment pumps and piping in the cistern room to support the barreling capacity increase. The existing piping system required reconfiguration to fix hydraulic issues with the existing pumps and integration of an additional product storage tank. To support the distillery’s addition of four barrel filling stations, we also replaced three barrel filling pumps, replaced and relocated current truck loading pump, and upsized the piping to increase flow rate through the system. And finally, we installed new plate packs in the two existing plate and frame whiskey coolers, upgraded tank instrumentation, and audited the system.

C&I was able to achieve all of this while incorporating client’s specific requests and staying flexible with changes in scope.