Crude Unit Flexibility

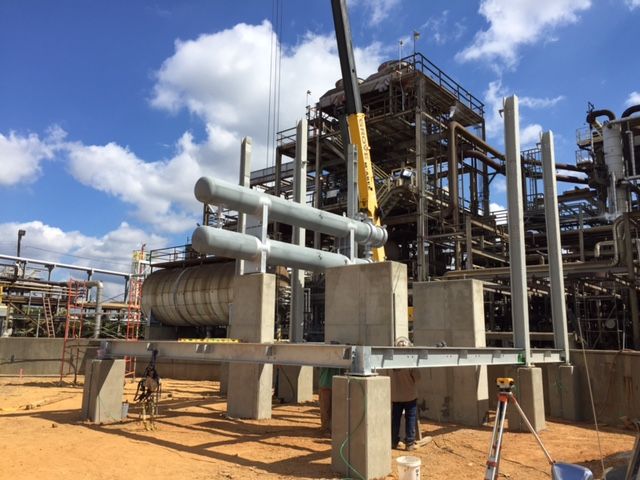

C&I completed the Feasibility through Detailed Design phases of the Crude Unit Flexibility and Optimization project, resulting in a ROI of less than 6 months. During Feasibility, C&I performed a debottlenecking study of the unit alongside our client counterpart to increase overall production capability, process a wider variety of crude slates, and produce two different grades of asphalt based on the crude oil. As a result, the Atmospheric Tower was repacked and a Shoepentoeter inlet device was added. The Vacuum Tower underwent significant modifications as well including repacking, adding an upper diesel draw, replacement of the transfer line between the heater and tower, and addition of several exchangers for heat integration.

Being the oldest unit in the refinery, the area was extremely congested. Therefore, C&I’s team utilized the laser scanning and 3D modeling tools to locate the new equipment and design piping. Due to real estate constraints, C&I’s team came up with a plan to place exchangers on an elevated structure to reduce impact to dike containment and avoid flooding.

Predicting 2-phase flow in the vacuum transfer line is challenging. C&I’s Senior Process Engineer, Russ Williams, presented his approach to the transfer line work in Hydrocarbon Processing article, “Simulation model of a vacuum heater transfer line,” in March, 2018.