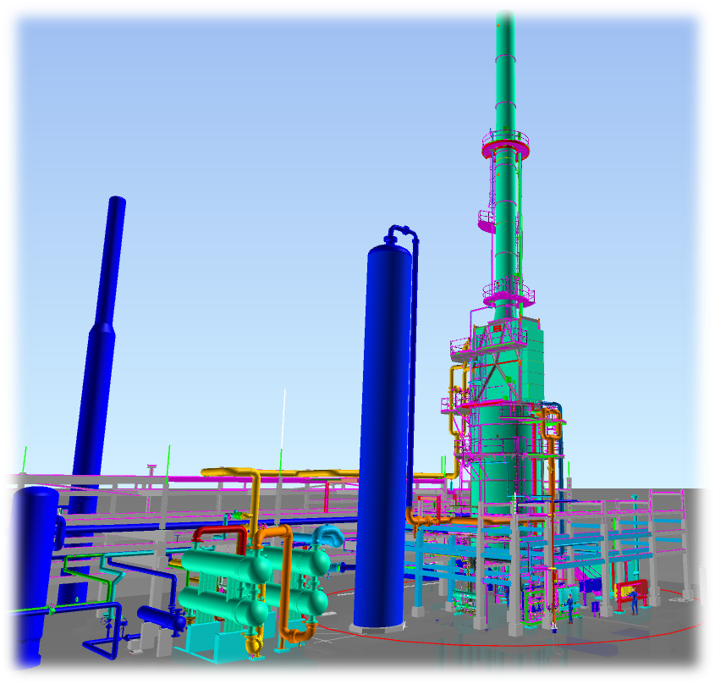

Hydrotreater Heater Replacement

C&I inherited this project from another engineering firm at the Detailed Design phase. Soon after the project began, the team was faced with challenges associated with the COVID pandemic. With limited travel, our team successfully worked remotely using a laser scan and field data gathered during the initial site visit. Our team overcame these obstacles to complete the engineering design ahead of schedule and under budget.

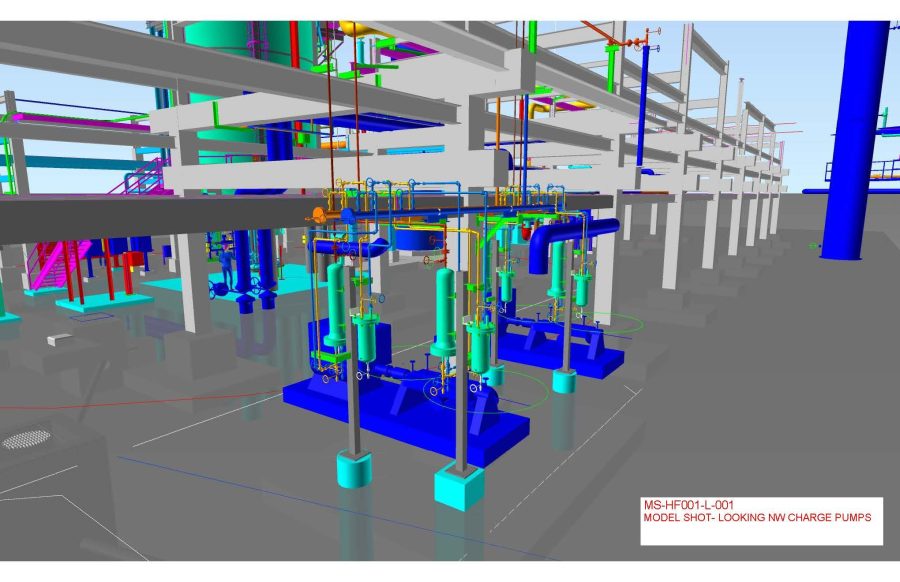

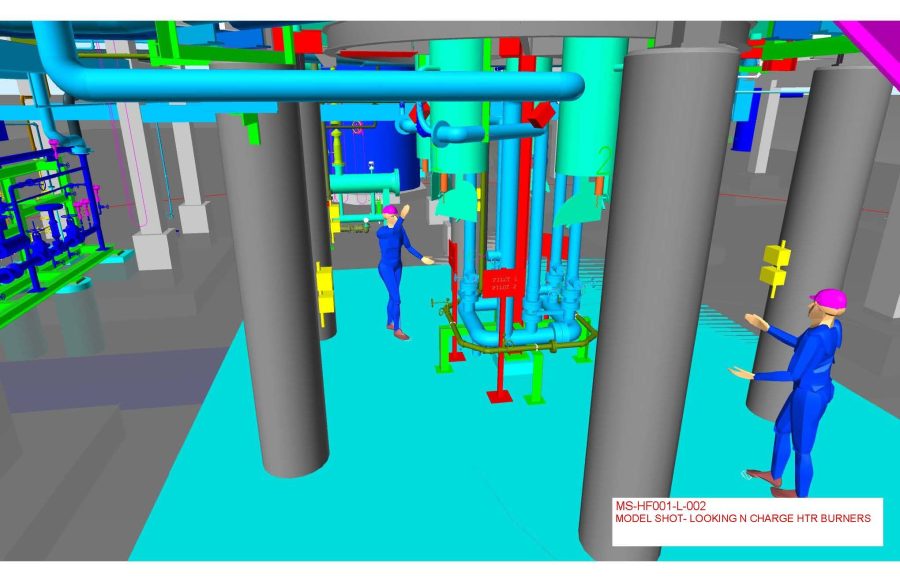

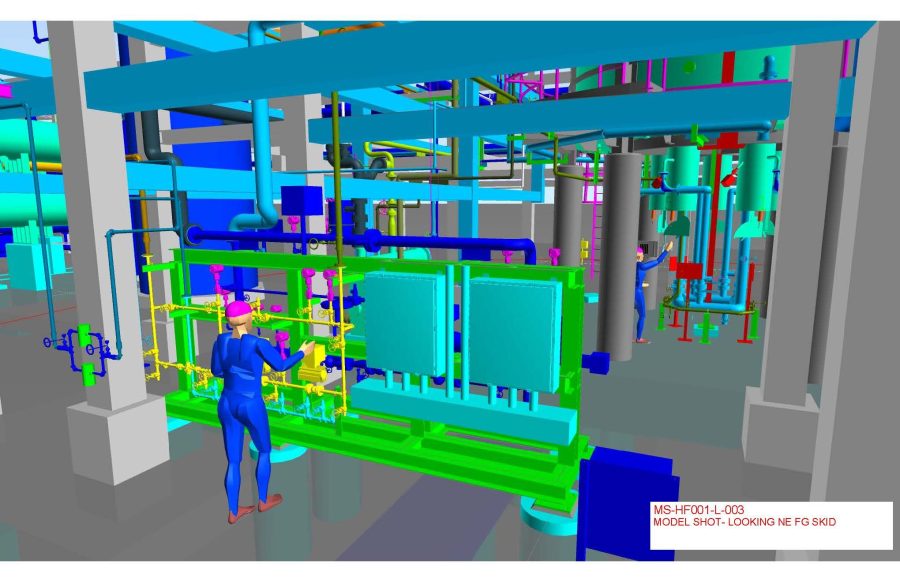

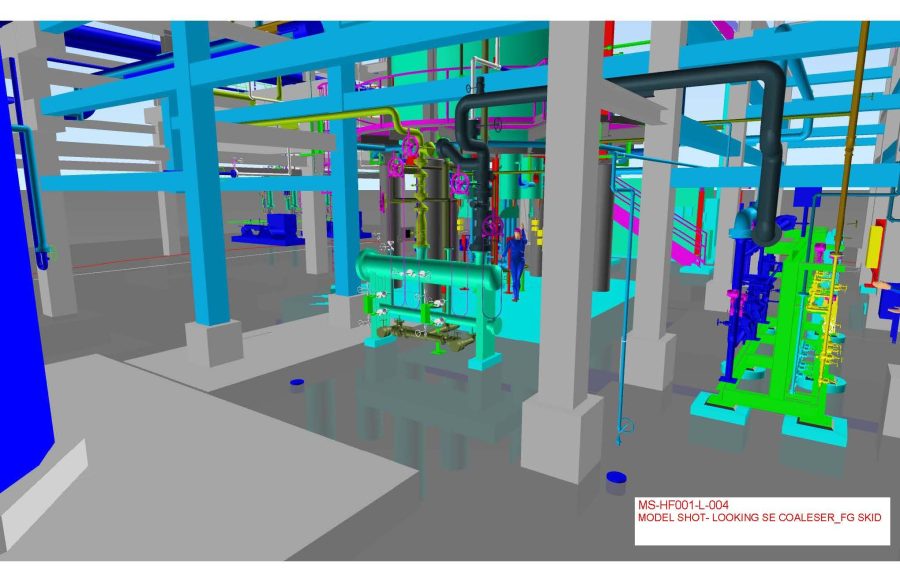

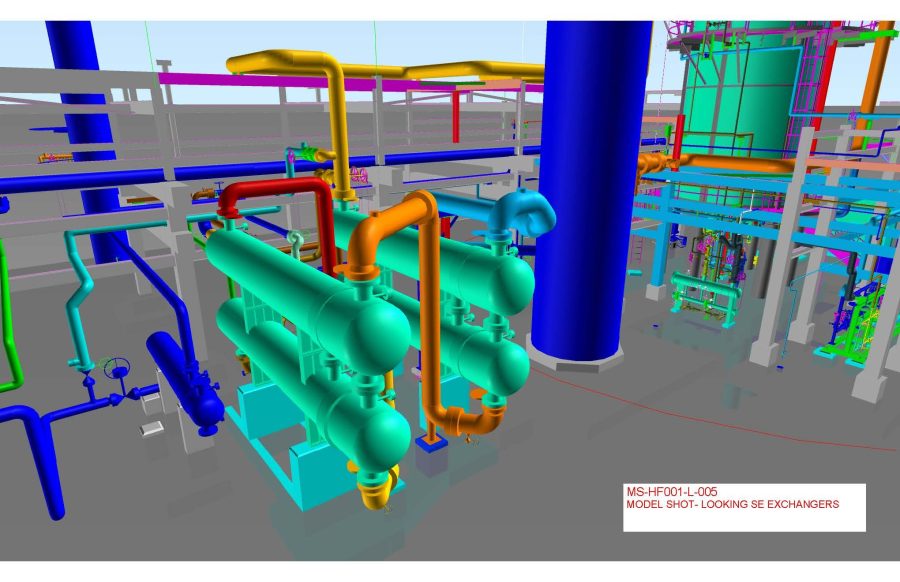

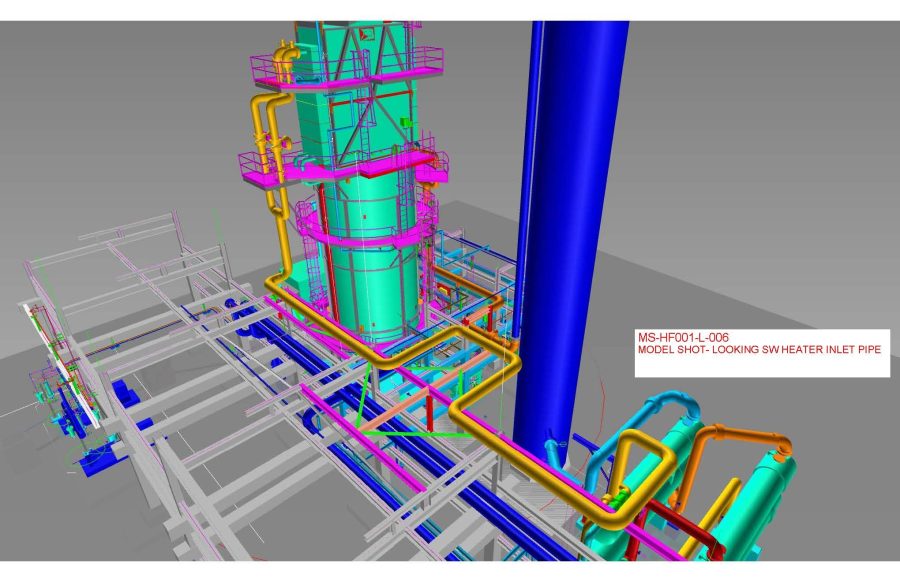

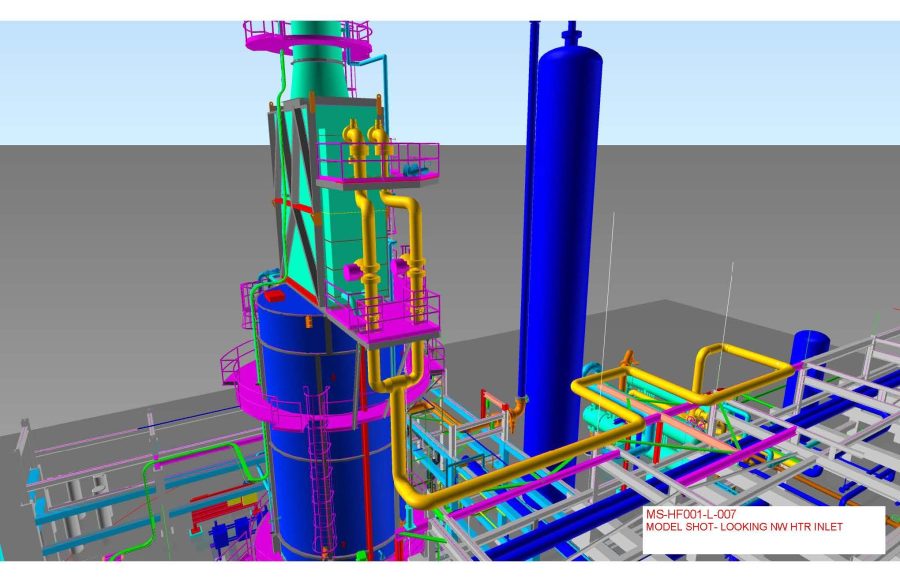

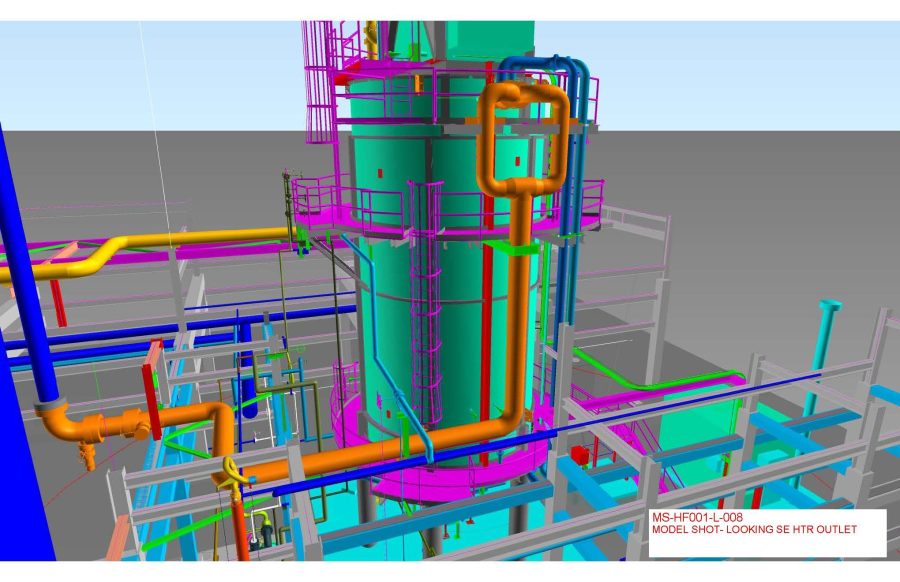

The scope of the project included a replacement heater with BMS (burner management system) and CEMS (continuous emissions monitoring system), new coalescing filter, and replacement of the charge/reactor effluent exchangers to debottleneck the unit and allow it to run at the hydraulic limit, increasing capacity by approximately 20%. Designing the piping to balance 2-phase flow was a critical project component. This was our first project with this client, and they were extremely happy with the execution of the project and how quickly our team learned their specifications.

“Our team was successful because we built relationships with the client team, specifically the Process and E&I representatives.”

Jason Cullens | Project Manager

This is an ongoing project. Our team is excited to see it through to installation!