NOx Abatement

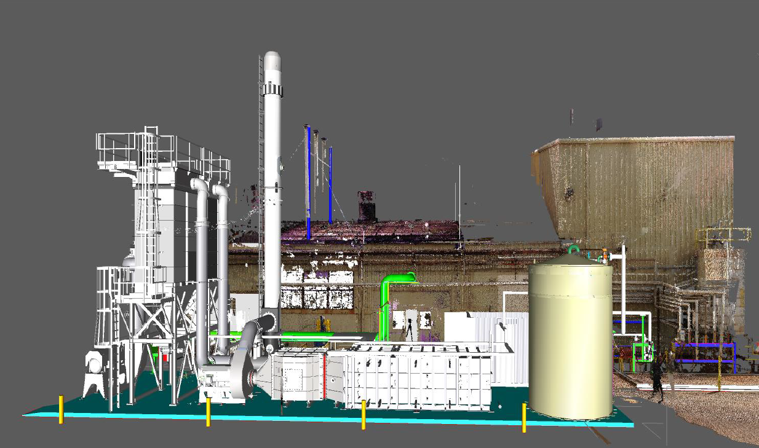

C&I assisted our client with specifying a SCR (selective catalyst reduction) system for removing NOx from rotary and belt calciners at a 95% or higher destruction efficiency. Defining the NOx emissions was challenging as the plant runs a variety of campaigns on each calciner resulting in several design cases used to characterize the NOx stream and establish a datasheet for the SCR unit. Several vendors and technologies were evaluated, and ultimately a system consisting of baghouse filters, natural gas burner, air fans, SCR catalyst reactor, exhaust stack, urea injection lance, mixers, and urea tank was chosen. Auxiliary equipment to the support the system included eductors for solids removal, air preheater to control header temperature, and a large collection header routed through the plant.

Utilizing our self-performed laser scan, the team was able to work with Operations, Construction and Maintenance to ensure the plant was able to use the existing NOx scrubber system while staging cut-over to the new system one calciner at a time, significantly reducing impacts to production.

C&I provided cost estimates for the FEL-3 and FEL-4 phases, procurement for instrumentation and engineered equipment, and construction packages for all upgrades.